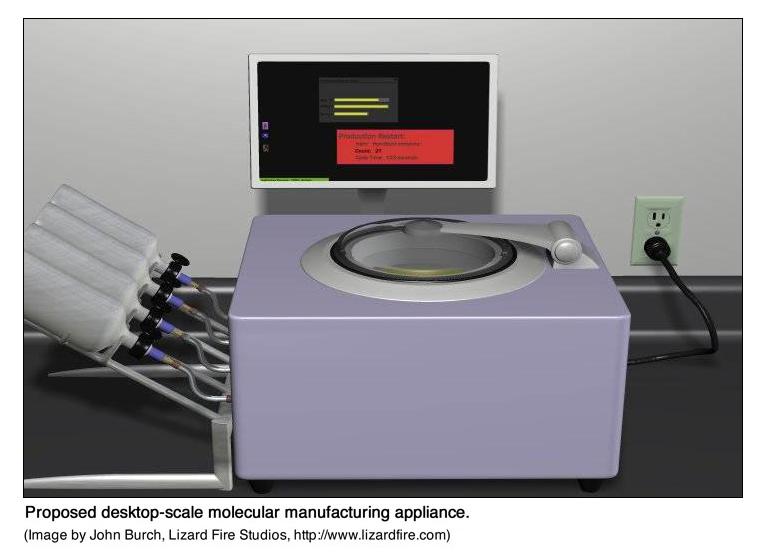

Now nanotechnology can be encapsulated in an apparently simple device called a personal nanofactory that may sit on your desktop. Packed with miniature chemical processors, computing, and robotics, it will produce a wide-range of items quickly, cleanly, and inexpensively, building products directly from blueprints.

To build a nanofactory, you need to start with a working fabricator, a nanoscale device that can combine individual molecules into useful shapes. A fabricator could build a very small nanofactory, which could build another one twice as big, and so on. Within a period of weeks, you have a personal desktop model. Products made by a nanofactory will be assembled from nanoblocks, which will be fabricated within the nanofactory. The product that comes out of the nanofactory will be a mostly-solid block or brick that will unfold like a pop-up book or inflate like an air mattress. Computer aided design (CAD) programs will make it possible to create state-of-the-art products simply by specifying a pattern of predesigned nanoblocks. The question of when we will see a flood of MNT products boils down to the question of how quickly the first fabricator can be designed and built.

A personal nanofactory will consist of trillions of fabricators, and could only be built by another nanofactory. But a fabricator could build a very small nanofactory, with just a few fabricators in it. A smaller nanofactory could build a bigger one, and so on. Most of the mass of a nanofactory is in the form of working fabricators, and according to the best estimates we have today, a fabricator could make its own mass in just a few hours. So a nanofactory could make another one twice as big in just a few days—maybe less than a day. Do that about sixty times, and you have a tabletop model.

Inside the personal nanofactory, each fabricator will make nanoblocks. A good size for a nanoblock might be a cube 200 nanometers on a side (the distance your fingernails grow in three minutes). This is small enough to be made by a single fabricator in a few hours, but large enough to contain a small CPU, a microwatt of motors or generators, or a fabricator system flexible enough to duplicate itself if given the right commands. In other words, each fabricator could make a substantial piece of nanofactory functionality—and the same modular pieces would be re-used in other products.

More >>>

|

0

comments

]

0 comments

Post a Comment